Are you looking for a career change or wanting to enhance your current skillset? Auto Windshield Repair Kits present a promising opportunity within the automotive industry. AUTO-REPAIR-TRAINING.EDU.VN offers comprehensive resources for those looking to enter this field, whether through formal training or by starting their own windshield repair business. Explore the world of auto windshield repair, understand the tools, techniques, and business acumen needed to succeed, and get information on ASE certifications, business plan development, and step-by-step guides.

Contents

- 1. What Are Auto Windshield Repair Kits and Why Are They Important?

- 1.1. Types of Windshield Damage Repairable with Kits

- 1.2. Benefits of Using Auto Windshield Repair Kits

- 2. Key Components of an Auto Windshield Repair Kit

- 2.1. Types of Resins Used in Windshield Repair

- 2.2. Essential Tools for Effective Windshield Repair

- 3. Choosing the Right Auto Windshield Repair Kit

- 3.1. Factors to Consider When Selecting a Repair Kit

- 3.2. Top-Rated Auto Windshield Repair Kits on the Market

- 4. Step-by-Step Guide to Using an Auto Windshield Repair Kit

- 4.1. Preparing the Windshield for Repair

- 4.2. Injecting the Resin and Curing Process

- 4.3. Finishing Touches for a Professional-Looking Repair

- 5. Common Mistakes to Avoid When Using Auto Windshield Repair Kits

- 5.1. Ensuring a Clean and Dry Surface

- 5.2. Proper Resin Application Techniques

- 5.3. Adequate Curing Time and Conditions

- 6. When to Seek Professional Windshield Repair Services

- 6.1. Limitations of DIY Windshield Repair Kits

- 6.2. Benefits of Professional Windshield Repair Services

- 7. The Science Behind Windshield Cracks and Repairs

- 7.1. Understanding Windshield Composition and Strength

- 7.2. How Resin Bonds with Glass to Restore Integrity

- 8. Exploring Career Opportunities in Auto Windshield Repair

- 8.1. Training and Certification for Windshield Repair Technicians

- 8.2. Starting Your Own Mobile Windshield Repair Business

- 9. The Environmental Impact of Windshield Repair vs. Replacement

- 9.1. Reducing Landfill Waste Through Windshield Repair

- 9.2. Conserving Energy and Resources with Windshield Repair

- 10. Future Trends in Auto Windshield Repair Technology

- 10.1. Innovations in Resin Technology

- 10.2. The Role of Technology in Enhancing Repair Precision

- FAQ: Auto Windshield Repair Kits

1. What Are Auto Windshield Repair Kits and Why Are They Important?

Auto windshield repair kits are comprehensive sets of tools and materials designed to fix minor damage to vehicle windshields, such as chips, cracks, and bullseyes. These kits are essential because they offer a cost-effective and convenient way to restore the structural integrity and clarity of a windshield, preventing further damage and ensuring driver safety.

- Cost-Effectiveness: Repairing a windshield is significantly cheaper than replacing it.

- Safety: Restoring the windshield’s integrity prevents further cracking and potential hazards.

- Convenience: Kits allow for quick repairs, saving time and hassle.

The importance of auto windshield repair kits extends beyond mere convenience. A damaged windshield can impair visibility, posing a safety risk to drivers and passengers. Moreover, unrepaired damage can lead to more extensive cracks, necessitating a full windshield replacement, which is a more costly and time-consuming process.

1.1. Types of Windshield Damage Repairable with Kits

Auto windshield repair kits are designed to address specific types of minor windshield damage. Knowing what kind of damage can be effectively repaired with these kits helps in making informed decisions about when to opt for repair versus replacement.

- Chips: Small, circular or semi-circular damages typically caused by small rocks or debris.

- Cracks: Linear fractures in the windshield glass. Kits can repair cracks up to a certain length.

- Bullseyes: Circular impact points with a visible center point, resembling a bullseye target.

- Star Breaks: A central impact point with several short cracks radiating outwards in a star pattern.

1.2. Benefits of Using Auto Windshield Repair Kits

Using auto windshield repair kits offers several advantages, both economically and practically. These benefits make them a valuable option for vehicle owners looking to maintain their windshields in optimal condition.

- Cost Savings: Repairing small damages is far less expensive than replacing the entire windshield.

- Time Efficiency: Repairs can often be completed in under an hour, minimizing vehicle downtime.

- Prevention of Further Damage: Addressing minor issues early prevents them from becoming larger cracks.

- Preservation of Original Seal: Repairing maintains the original factory seal, which can be compromised during replacement.

- Environmental Benefits: Repairing instead of replacing reduces waste and energy consumption associated with manufacturing new windshields.

2. Key Components of an Auto Windshield Repair Kit

Understanding the components of an auto windshield repair kit is essential for anyone looking to perform windshield repairs effectively. Each element plays a crucial role in the repair process, from preparing the damaged area to injecting the resin and achieving a clear, durable finish.

- Resin: A specially formulated adhesive that fills the damaged area, restoring the windshield’s structural integrity and clarity.

- Injector: A device used to create a vacuum and inject the resin into the damaged area.

- Bridge: A frame that holds the injector in place and applies pressure to ensure proper resin penetration.

- Curing Strips: Transparent films placed over the repaired area to protect the resin while it cures under UV light.

- UV Light: Used to harden the resin, creating a durable and transparent bond.

- Drill: A small drill bit used to create a clean entry point for the resin, especially for certain types of damage.

- Cleaning Solution: Used to clean the damaged area, removing dirt and debris to ensure a strong bond.

- Razor Blade: Used to remove excess resin and smooth the repaired surface for a seamless finish.

2.1. Types of Resins Used in Windshield Repair

The type of resin used in an auto windshield repair kit is crucial for the success and longevity of the repair. Different resins are formulated for specific types of damage and environmental conditions.

- Standard Resin: Suitable for most common types of damage, such as chips and small cracks.

- Crack-Specific Resin: Designed for longer cracks, with properties that allow it to flow easily and fill the entire crack.

- High-Viscosity Resin: Used for larger or more complex damage, providing extra strength and durability.

- UV-Resistant Resin: Formulated to resist yellowing and degradation from prolonged exposure to sunlight.

2.2. Essential Tools for Effective Windshield Repair

Besides the resin, several tools are essential for performing effective windshield repairs. These tools ensure precision, proper resin penetration, and a professional finish.

- Inspection Mirror: Helps to examine the damage closely and ensure thorough cleaning.

- Probe: Used to remove loose glass fragments and debris from the damaged area.

- Polishing Compound: Applied after curing to smooth the repaired surface and enhance clarity.

- Heat Gun: Used to warm the windshield slightly, improving resin flow and adhesion.

- Safety Glasses: Protects the eyes from glass fragments and UV light.

- Gloves: Keeps hands clean and protects them from chemicals.

3. Choosing the Right Auto Windshield Repair Kit

Selecting the right auto windshield repair kit is crucial for achieving successful and lasting repairs. With numerous options available, it’s important to consider several factors to ensure the kit meets your specific needs and skill level.

- Type of Damage: Match the kit to the type of damage you need to repair (chips, cracks, bullseyes).

- Quality of Resin: Opt for kits with high-quality, UV-resistant resin for durability and clarity.

- Tool Included: Ensure the kit includes all necessary tools for a complete repair process.

- User-Friendliness: Choose a kit with clear instructions and easy-to-use tools, especially if you’re a beginner.

- Customer Reviews: Check reviews and ratings to gauge the kit’s effectiveness and reliability.

- Price: Balance cost with quality, ensuring you get a kit that offers good value for your money.

3.1. Factors to Consider When Selecting a Repair Kit

When choosing an auto windshield repair kit, several factors should be taken into account to ensure you select the most appropriate kit for your needs.

- Size and Complexity of Damage: Larger or more complex damages may require a more comprehensive kit.

- Skill Level: Beginners should opt for user-friendly kits with detailed instructions.

- Frequency of Use: If you plan to perform repairs frequently, invest in a higher-quality kit with durable tools.

- Environmental Conditions: Consider UV exposure and temperature variations in your area when selecting resin.

- Warranty: Check if the kit comes with a warranty or satisfaction guarantee.

- Brand Reputation: Choose a kit from a reputable brand known for quality and reliability.

3.2. Top-Rated Auto Windshield Repair Kits on the Market

Exploring some of the top-rated auto windshield repair kits available can help narrow down your options and ensure you invest in a reliable product.

- Esqure Windshield Repair Kit: Known for its ease of use and effectiveness on small chips and cracks.

- Rain-X Windshield Repair Kit: A popular choice for its high-quality resin and comprehensive tool set.

- GlasWeld ProVac Zoom Windshield Repair Kit: A professional-grade kit suitable for a wide range of damages.

- Blue-Star Windshield Repair Kit: Offers a balance of quality and affordability, ideal for DIY enthusiasts.

- Permatex Windshield Repair Kit: Known for its strong and durable resin, suitable for various types of damage.

4. Step-by-Step Guide to Using an Auto Windshield Repair Kit

Using an auto windshield repair kit involves a series of steps to ensure the damage is properly filled and the windshield’s integrity is restored. Following these steps carefully will help you achieve a professional-quality repair.

- Clean the Damaged Area: Use the provided cleaning solution to remove dirt and debris from the damaged area.

- Apply the Injector: Attach the injector to the windshield, ensuring it is centered over the damage.

- Inject the Resin: Fill the injector with resin and apply pressure to force it into the damaged area.

- Cure the Resin: Place a curing strip over the repaired area and expose it to UV light for the recommended time.

- Remove Excess Resin: Use a razor blade to carefully remove any excess resin and smooth the surface.

- Polish the Surface: Apply polishing compound to the repaired area to enhance clarity and smoothness.

4.1. Preparing the Windshield for Repair

Proper preparation is crucial for a successful windshield repair. This involves cleaning the damaged area thoroughly and creating a clean entry point for the resin.

- Cleaning: Use a specialized cleaning solution to remove dirt, oil, and loose glass fragments.

- Drying: Ensure the area is completely dry before proceeding.

- Creating an Entry Point: If necessary, use a small drill bit to create a clean entry point for the resin.

- Removing Air Pockets: Use a probe to eliminate any air pockets within the damaged area.

4.2. Injecting the Resin and Curing Process

The injection and curing process are critical steps in restoring the windshield’s structural integrity and clarity.

- Injecting Resin: Fill the injector with the appropriate type of resin, ensuring no air bubbles are present.

- Applying Pressure: Use the injector to apply consistent pressure, forcing the resin into the damaged area.

- Monitoring Resin Flow: Observe the resin flow to ensure it fills all cracks and voids.

- Curing: Place a curing strip over the repaired area and expose it to UV light for the recommended duration, typically 5-10 minutes.

- Checking for Full Cure: Ensure the resin is fully hardened before removing the curing strip.

Windshield chip repair kit resin injector applying pressure

Windshield chip repair kit resin injector applying pressure

4.3. Finishing Touches for a Professional-Looking Repair

Achieving a professional-looking repair involves several finishing touches that enhance clarity and smoothness.

- Removing Excess Resin: Use a razor blade to carefully scrape off any excess resin, holding the blade at a low angle to avoid scratching the glass.

- Polishing: Apply a small amount of polishing compound to a soft cloth and buff the repaired area to remove any remaining imperfections.

- Cleaning: Wipe the area with a clean cloth to remove any polishing residue.

- Inspection: Inspect the repair closely to ensure it is smooth, clear, and free of any visible imperfections.

5. Common Mistakes to Avoid When Using Auto Windshield Repair Kits

While auto windshield repair kits are designed to be user-friendly, certain mistakes can compromise the quality and longevity of the repair. Avoiding these common pitfalls ensures a successful outcome.

- Using the Wrong Type of Resin: Always select a resin that is appropriate for the type and size of damage.

- Insufficient Cleaning: Failure to thoroughly clean the damaged area can prevent proper resin adhesion.

- Applying Too Much Pressure: Over-pressurizing the injector can cause further cracking.

- Inadequate Curing: Insufficient curing time can result in a soft, unstable repair.

- Ignoring Instructions: Always follow the manufacturer’s instructions carefully.

- Attempting to Repair Large Cracks: Auto repair kits are designed for minor damage only.

5.1. Ensuring a Clean and Dry Surface

A clean and dry surface is essential for proper resin adhesion and a successful repair.

- Use the Right Cleaner: Opt for a specialized windshield cleaning solution that removes contaminants without leaving residue.

- Scrub Thoroughly: Use a soft brush or cloth to scrub the damaged area, ensuring all dirt and debris are removed.

- Rinse and Dry: Rinse the area with clean water and dry it thoroughly with a lint-free cloth or compressed air.

- Inspect Carefully: Use a magnifying glass or inspection mirror to ensure no contaminants remain.

5.2. Proper Resin Application Techniques

Applying resin correctly ensures it fills all cracks and voids, restoring the windshield’s structural integrity.

- Avoid Air Bubbles: Ensure the resin is free of air bubbles before injecting it into the damaged area.

- Apply Steady Pressure: Use the injector to apply consistent pressure, allowing the resin to flow evenly.

- Monitor Resin Flow: Observe the resin flow to ensure it fills all cracks and voids completely.

- Don’t Overfill: Avoid overfilling the damaged area, as excess resin can be difficult to remove.

5.3. Adequate Curing Time and Conditions

Proper curing is crucial for hardening the resin and creating a durable, long-lasting repair.

- Use UV Light: Expose the repaired area to UV light for the recommended duration, typically 5-10 minutes.

- Optimal Temperature: Perform the curing process in a temperature-controlled environment, ideally between 70-80°F.

- Avoid Direct Sunlight: Do not cure the resin in direct sunlight, as it can cause uneven hardening.

- Check for Full Cure: Ensure the resin is fully hardened before removing the curing strip.

6. When to Seek Professional Windshield Repair Services

While auto windshield repair kits are effective for minor damages, certain situations require professional intervention. Recognizing these scenarios ensures the safety and integrity of your vehicle.

- Large or Complex Cracks: Cracks longer than 12 inches or those that branch out in multiple directions.

- Damage in the Driver’s Line of Sight: Repairs in this area can distort vision and compromise safety.

- Multiple Damage Points: Numerous chips or cracks that weaken the windshield’s structure.

- Deep Damage: Damage that penetrates multiple layers of glass.

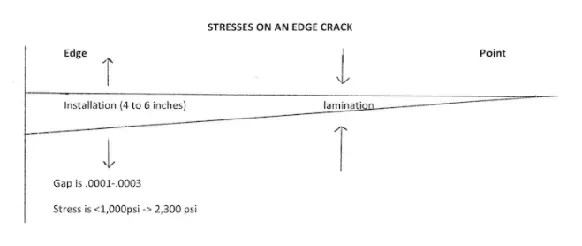

- Edge Cracks: Cracks that extend to the edge of the windshield.

6.1. Limitations of DIY Windshield Repair Kits

DIY windshield repair kits have limitations and are not suitable for all types of damage.

- Skill Required: Achieving a professional-quality repair requires skill and experience.

- Tool Limitations: DIY kits may lack the specialized tools needed for complex repairs.

- Resin Quality: The resin in DIY kits may not be as high-quality as that used by professionals.

- Warranty Concerns: DIY repairs may void the vehicle’s warranty or insurance coverage.

- Safety Issues: Improper repairs can compromise the windshield’s structural integrity and safety.

6.2. Benefits of Professional Windshield Repair Services

Opting for professional windshield repair services offers several advantages over DIY kits.

- Expertise and Experience: Professionals have the knowledge and experience to assess and repair a wide range of damages.

- High-Quality Materials: Professionals use high-quality resins and tools that ensure a durable and long-lasting repair.

- Warranty Coverage: Professional repairs typically come with a warranty, providing peace of mind.

- Insurance Claims: Professionals can often handle insurance claims, simplifying the process for the vehicle owner.

- Safety Assurance: Professional repairs ensure the windshield’s structural integrity is fully restored, enhancing safety.

7. The Science Behind Windshield Cracks and Repairs

Understanding the science behind windshield cracks and repairs provides valuable insight into the effectiveness of auto windshield repair kits.

- Composition of Windshields: Windshields are made of two layers of glass with a layer of polyvinyl butyral (PVB) in between.

- Causes of Cracks: Cracks typically occur due to impact, temperature changes, or stress.

- Repair Process: Resin fills the cracks and bonds to the glass, restoring structural integrity.

- UV Curing: UV light hardens the resin, creating a durable and transparent bond.

- Stress Distribution: Proper repair distributes stress evenly, preventing further cracking.

7.1. Understanding Windshield Composition and Strength

Knowing the composition of windshields helps in understanding their strength and vulnerability to damage.

- Laminated Glass: Windshields are made of laminated glass, which consists of two layers of glass bonded together with a layer of polyvinyl butyral (PVB).

- PVB Layer: The PVB layer provides flexibility and prevents the glass from shattering upon impact.

- Strength and Durability: Laminated glass is designed to withstand significant impact and provide structural support to the vehicle.

- Vulnerability: Despite its strength, laminated glass is vulnerable to chips, cracks, and other types of damage.

7.2. How Resin Bonds with Glass to Restore Integrity

The bonding process between resin and glass is critical for restoring the windshield’s structural integrity.

- Resin Properties: Windshield repair resins are specially formulated to bond with glass at a molecular level.

- Capillary Action: The resin flows into cracks and voids through capillary action, filling them completely.

- Adhesion: The resin adheres to the glass surfaces, creating a strong and durable bond.

- Curing Process: UV light hardens the resin, forming a permanent bond that restores the windshield’s strength and clarity.

- Stress Distribution: The repaired area distributes stress evenly, preventing further cracking and damage.

8. Exploring Career Opportunities in Auto Windshield Repair

The auto windshield repair industry offers various career opportunities for those interested in automotive services.

- Windshield Repair Technician: Repairing and replacing windshields for auto repair shops or mobile service providers.

- Mobile Windshield Repair Specialist: Providing on-site repair services to customers at their homes or workplaces.

- Auto Glass Installer: Installing new windshields and auto glass for vehicle owners.

- Shop Owner: Starting and managing your own windshield repair business.

8.1. Training and Certification for Windshield Repair Technicians

Proper training and certification can enhance your skills and credibility as a windshield repair technician.

- Vocational Schools: Enroll in vocational schools offering auto glass repair and replacement programs.

- On-the-Job Training: Gain practical experience through on-the-job training with established repair shops.

- Certification Programs: Obtain certifications from industry organizations, such as the National Windshield Repair Association (NWRA).

- Continuing Education: Stay updated with the latest techniques and technologies through continuing education courses.

8.2. Starting Your Own Mobile Windshield Repair Business

Starting a mobile windshield repair business can be a lucrative venture with low overhead costs.

- Business Plan: Develop a comprehensive business plan outlining your services, target market, and financial projections.

- Equipment and Supplies: Invest in high-quality windshield repair kits, tools, and supplies.

- Licensing and Insurance: Obtain the necessary licenses and insurance to operate legally in your area.

- Marketing: Promote your services through online advertising, social media, and local partnerships.

- Customer Service: Provide excellent customer service to build a loyal customer base.

9. The Environmental Impact of Windshield Repair vs. Replacement

Choosing windshield repair over replacement has significant environmental benefits, contributing to sustainability efforts.

- Reduced Waste: Repairing reduces the amount of glass and materials sent to landfills.

- Energy Conservation: Manufacturing new windshields requires significant energy, which is avoided through repair.

- Lower Carbon Footprint: Repairing has a lower carbon footprint compared to the energy-intensive process of producing new windshields.

- Resource Preservation: Repairing helps conserve natural resources used in glass manufacturing.

- Sustainable Practices: Choosing repair supports sustainable practices and reduces environmental impact.

9.1. Reducing Landfill Waste Through Windshield Repair

Windshield repair plays a crucial role in reducing landfill waste and promoting environmental conservation.

- Glass Recycling Challenges: Recycling windshield glass is complex and not always feasible.

- Landfill Capacity: Landfills are reaching capacity, making waste reduction essential.

- Repair as a Solution: Repairing extends the life of the windshield and prevents it from ending up in a landfill.

- Environmental Benefits: Reducing landfill waste conserves natural resources and minimizes environmental pollution.

9.2. Conserving Energy and Resources with Windshield Repair

Repairing windshields conserves energy and resources, contributing to a more sustainable automotive industry.

- Energy-Intensive Manufacturing: Manufacturing new windshields requires significant energy for melting, molding, and processing glass.

- Resource Depletion: Glass manufacturing consumes natural resources, such as sand, soda ash, and limestone.

- Repair as a Conservation Method: Repairing reduces the demand for new windshields, conserving energy and resources.

- Sustainable Practices: Choosing repair supports sustainable practices and reduces environmental impact.

10. Future Trends in Auto Windshield Repair Technology

The auto windshield repair industry is continuously evolving with advancements in technology and techniques.

- Advanced Resin Formulations: Development of stronger, more durable, and UV-resistant resins.

- Smart Repair Systems: Integration of sensors and diagnostic tools for precise damage assessment and repair.

- Robotics: Use of robots for automated windshield repair processes.

- Eco-Friendly Materials: Adoption of sustainable and environmentally friendly repair materials.

- Remote Diagnostics: Remote assessment of windshield damage using mobile apps and imaging technology.

10.1. Innovations in Resin Technology

Resin technology is at the forefront of advancements in auto windshield repair.

- Self-Healing Resins: Development of resins that can automatically repair minor damages.

- Nanomaterials: Incorporation of nanomaterials to enhance resin strength, durability, and clarity.

- Adaptive Resins: Resins that adjust their properties based on environmental conditions.

- UV-Activated Adhesives: Adhesives that cure quickly and efficiently under UV light.

- Biodegradable Resins: Development of biodegradable resins to reduce environmental impact.

10.2. The Role of Technology in Enhancing Repair Precision

Technology plays a vital role in enhancing the precision and effectiveness of windshield repairs.

- Laser Repair Systems: Use of lasers to precisely remove damaged glass and prepare the surface for resin injection.

- 3D Scanning: 3D scanning technology to map the damage and create a customized repair plan.

- Automated Injectors: Computer-controlled injectors that deliver resin with precise pressure and flow rates.

- Diagnostic Tools: Sensors and diagnostic tools that assess the damage and monitor the repair process.

- Augmented Reality: Augmented reality apps that guide technicians through the repair process.

FAQ: Auto Windshield Repair Kits

Here are some frequently asked questions about auto windshield repair kits:

1. What types of windshield damage can be repaired with a kit?

Auto windshield repair kits are effective for minor damages like chips, small cracks (up to 12 inches), bullseyes, and star breaks.

2. How much does an auto windshield repair kit cost?

The cost varies from $10 for basic kits to $100 or more for professional-grade kits.

3. Can I use a repair kit on any type of windshield?

Yes, repair kits are generally safe for all types of laminated windshields.

4. How long does it take to repair a windshield with a kit?

Most repairs can be completed in 30 minutes to an hour.

5. Is it easy to use an auto windshield repair kit?

Yes, most kits are designed for DIY use with clear instructions, but skill and practice are required for best results.

6. Will the repair be invisible?

While the repair will improve clarity and structural integrity, it may not be completely invisible.

7. Is it better to repair or replace a damaged windshield?

Repairing is usually better for minor damage as it’s cheaper and maintains the original seal, while replacement is necessary for extensive damage.

8. Can I claim the repair cost from my insurance company?

Some insurance policies cover windshield repairs, so check with your provider.

9. What are the limitations of DIY windshield repair kits?

DIY kits may not be suitable for large or complex cracks, and the quality may not match professional repairs.

10. Where can I learn more about windshield repair training and business opportunities?

AUTO-REPAIR-TRAINING.EDU.VN offers comprehensive resources for training and starting your own windshield repair business.

Auto windshield repair kits offer a practical and cost-effective solution for maintaining the integrity and clarity of your vehicle’s windshield. By understanding the components, techniques, and limitations of these kits, you can make informed decisions about when to repair and when to seek professional help. For those looking to turn this skill into a career, AUTO-REPAIR-TRAINING.EDU.VN provides the training and resources needed to succeed. Whether you’re interested in becoming a certified technician or starting your own mobile repair business, the opportunities are vast and rewarding. Explore our programs and take the first step towards a successful career in auto windshield repair. Contact us at +1 (641) 206-8880 or visit our office at 200 N Michigan Ave, Suite 1500, Chicago, IL 60601, United States. Visit AUTO-REPAIR-TRAINING.EDU.VN today.