Auto Wiring Repair is a critical skill for anyone involved in the automotive industry, and mastering it opens up a world of career opportunities. AUTO-REPAIR-TRAINING.EDU.VN is your ultimate resource for comprehensive training and guidance, whether you’re a student, career changer, experienced technician, or aspiring shop owner. We provide the knowledge and skills you need to excel in auto wiring repair and the broader automotive field.

Contents

- 1. Why is Auto Wiring Repair a Crucial Skill?

- 2. Who Needs Auto Wiring Repair Training?

- 3. Understanding the Basics of Automotive Electrical Systems

- 4. Common Auto Wiring Problems and How to Diagnose Them

- 5. Tools and Equipment for Auto Wiring Repair

- 6. Step-by-Step Guide to Auto Wiring Repair

- 7. Advanced Auto Wiring Techniques

- 8. Safety Precautions for Auto Wiring Repair

- 9. Choosing the Right Auto Wiring Repair Training Program

- 10. Career Opportunities in Auto Wiring Repair

- 11. Starting Your Own Auto Repair Shop: A Comprehensive Guide

- 12. The Business Side of Auto Repair: Essential Tips for Success

- 13. Staying Up-to-Date with Auto Wiring Technology

- 14. Frequently Asked Questions (FAQs) About Auto Wiring Repair

- 15. AUTO-REPAIR-TRAINING.EDU.VN: Your Partner in Automotive Success

Table of Contents

- Why is Auto Wiring Repair a Crucial Skill?

- Who Needs Auto Wiring Repair Training?

- Understanding the Basics of Automotive Electrical Systems

- Common Auto Wiring Problems and How to Diagnose Them

- Tools and Equipment for Auto Wiring Repair

- Step-by-Step Guide to Auto Wiring Repair

- Advanced Auto Wiring Techniques

- Safety Precautions for Auto Wiring Repair

- Choosing the Right Auto Wiring Repair Training Program

- Career Opportunities in Auto Wiring Repair

- Starting Your Own Auto Repair Shop: A Comprehensive Guide

- The Business Side of Auto Repair: Essential Tips for Success

- Staying Up-to-Date with Auto Wiring Technology

- Frequently Asked Questions (FAQs) About Auto Wiring Repair

- AUTO-REPAIR-TRAINING.EDU.VN: Your Partner in Automotive Success

1. Why is Auto Wiring Repair a Crucial Skill?

Are auto wiring repairs essential for modern vehicles? Yes, they are. Modern vehicles are increasingly reliant on complex electrical systems for everything from engine management to safety features and comfort.

Auto wiring repair is a crucial skill for several reasons:

- Complexity of Modern Vehicles: Modern cars are packed with sophisticated electronics, making wiring systems more complex than ever before.

- Diagnostic Skills: Wiring issues often cause a variety of problems, requiring skilled technicians to diagnose and repair them accurately.

- Safety: Faulty wiring can lead to safety hazards like fires or malfunctioning safety systems (ABS, airbags), making proper repair essential.

- Cost Savings: Addressing wiring issues promptly can prevent more extensive damage and costly repairs down the road.

- Job Security: As vehicles become more technologically advanced, the demand for skilled auto wiring technicians will continue to grow.

2. Who Needs Auto Wiring Repair Training?

Who benefits most from auto wiring repair training? Students, career changers, and experienced technicians all stand to gain from specialized training in this area.

Auto wiring repair training is beneficial for a wide range of individuals:

- Students: Those considering a career as an automotive technician can gain a valuable specialization.

- Career Changers: Individuals looking to switch to the automotive industry can acquire a high-demand skill.

- Experienced Technicians: Seasoned mechanics can upgrade their skills to work on modern, technologically advanced vehicles.

- DIY Enthusiasts: Car enthusiasts can learn to perform basic wiring repairs on their own vehicles.

- Aspiring Shop Owners: Understanding auto wiring repair is crucial for managing a successful auto repair business.

3. Understanding the Basics of Automotive Electrical Systems

What are the fundamental components of an automotive electrical system? Batteries, alternators, starters, and wiring harnesses form the backbone of any vehicle’s electrical network.

To effectively perform auto wiring repair, it’s essential to understand the basics of automotive electrical systems:

- Battery: Provides the initial power to start the engine and operate electrical components.

- Alternator: Recharges the battery while the engine is running and supplies power to the electrical system.

- Starter: An electric motor that cranks the engine to start it.

- Wiring Harness: A network of wires that connects all the electrical components in the vehicle.

- Fuses and Circuit Breakers: Protect the electrical system from overloads and short circuits.

- Relays: Electrically operated switches that control high-current circuits.

- Sensors: Devices that monitor various parameters (temperature, pressure, speed) and send signals to the engine control unit (ECU).

- Actuators: Devices that perform actions based on signals from the ECU (fuel injectors, solenoids, motors).

- ECU (Engine Control Unit): The “brain” of the engine, which controls various functions based on sensor inputs.

4. Common Auto Wiring Problems and How to Diagnose Them

What are some typical auto wiring problems technicians encounter? Broken wires, corroded connections, short circuits, and open circuits are among the most frequent issues.

Several common auto wiring problems can plague vehicles:

- Broken Wires: Wires can break due to age, stress, or physical damage.

- Corroded Connections: Corrosion can build up on electrical connectors, causing poor contact and intermittent problems.

- Short Circuits: A short circuit occurs when a wire accidentally touches ground, causing excessive current flow.

- Open Circuits: An open circuit occurs when a wire is broken or disconnected, preventing current from flowing.

- Loose Connections: Loose connections can cause intermittent problems and voltage drops.

- Damaged Insulation: Damaged wire insulation can lead to short circuits and electrical leaks.

Diagnosing Auto Wiring Problems

Effective diagnosis is critical for auto wiring repair. Here are some common diagnostic techniques:

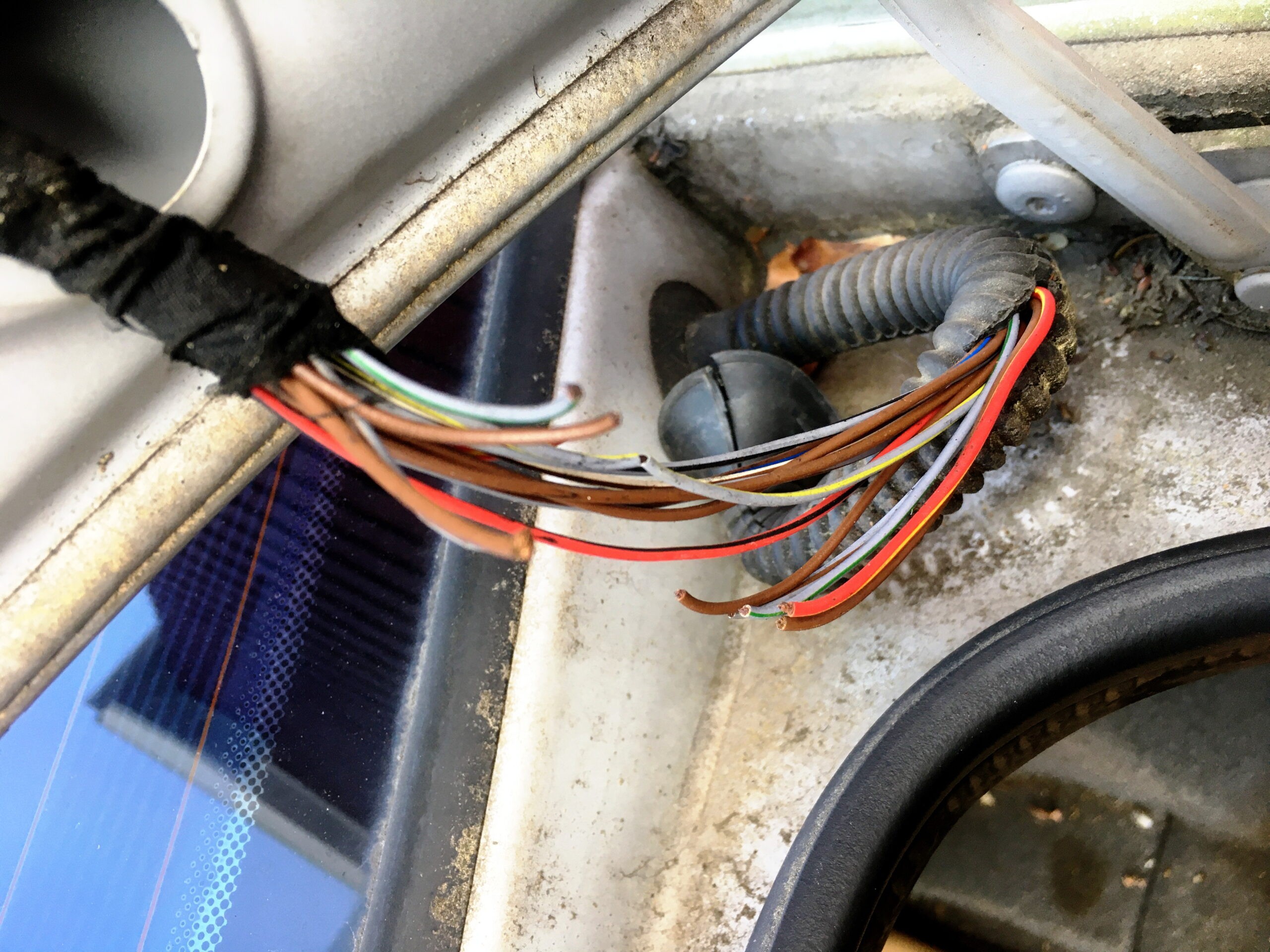

- Visual Inspection: Carefully inspect wires and connectors for signs of damage, corrosion, or loose connections.

car wiring closeup

car wiring closeup - Multimeter Testing: Use a multimeter to measure voltage, resistance, and current to identify circuit problems.

- Continuity Testing: Check for continuity in a circuit to ensure that wires are connected properly.

- Voltage Drop Testing: Measure voltage drops across a circuit to identify areas of excessive resistance.

- Scan Tool Diagnostics: Use a scan tool to read diagnostic trouble codes (DTCs) from the ECU, which can provide clues about wiring problems.

- Wiring Diagrams: Consult wiring diagrams to understand the layout of the electrical system and identify potential problem areas.

5. Tools and Equipment for Auto Wiring Repair

What tools are essential for auto wiring repair? Multimeters, wire strippers, crimpers, soldering irons, and heat guns are indispensable for any auto wiring technician.

Having the right tools and equipment is essential for performing auto wiring repair effectively and safely:

- Multimeter: Used to measure voltage, current, and resistance.

- Wire Strippers: Used to remove insulation from wires without damaging the conductors.

- Crimpers: Used to crimp terminals and connectors onto wires.

- Soldering Iron: Used to solder wires together for a secure and reliable connection.

- Heat Gun: Used to shrink heat-shrink tubing and connectors.

- Wiring Diagrams: Essential for understanding the layout of the electrical system.

- Terminal Removal Tools: Used to remove terminals from connectors without damaging them.

- Test Light: A simple tool for checking voltage in a circuit.

- Continuity Tester: Used to check for continuity in a circuit.

- Wire Fish Tape: Used to pull wires through tight spaces.

- Electrical Tape: Used to insulate and protect wires.

- Heat-Shrink Tubing: Used to insulate and protect wire splices.

- Assorted Terminals and Connectors: A variety of terminals and connectors are needed to make repairs.

6. Step-by-Step Guide to Auto Wiring Repair

What’s the process for repairing a broken wire in a vehicle? Start by disconnecting the battery, then strip, splice, solder, and insulate the wire for a secure repair.

Here’s a step-by-step guide to repairing a broken wire in an automotive electrical system:

-

Disconnect the Battery: Always disconnect the negative battery cable before working on electrical systems to prevent short circuits and electrical shock.

-

Identify the Broken Wire: Locate the broken wire and determine the extent of the damage.

car wiring cut closeup

car wiring cut closeup -

Strip the Wire Ends: Use wire strippers to carefully remove the insulation from the ends of the broken wire, exposing the bare conductors.

-

Splice the Wires: There are several ways to splice wires together:

- Butt Splice Connectors: Insert the stripped ends of the wire into a butt splice connector and crimp it securely.

car wiring connector

car wiring connector - Heat-Shrink Solder-Splice Connectors: Insert the stripped ends of the wire into a heat-shrink solder-splice connector, ensuring that the ends are inside the solder ring. Use a heat gun to melt the solder and shrink the tubing.

- Manual Soldering: Overlap the stripped ends of the wire, twist them together, and solder them using a soldering iron.

- Butt Splice Connectors: Insert the stripped ends of the wire into a butt splice connector and crimp it securely.

-

Insulate the Splice: Cover the splice with electrical tape or heat-shrink tubing to insulate it and protect it from the elements.

-

Secure the Wire: Secure the repaired wire to the wiring harness using zip ties or electrical tape.

-

Reconnect the Battery: Reconnect the negative battery cable and test the circuit to ensure that it is working properly.

7. Advanced Auto Wiring Techniques

What are some advanced auto wiring techniques for complex repairs? These include diagnosing CAN bus systems, repairing fiber optic cables, and using advanced diagnostic tools.

Advanced auto wiring repair involves working with complex electrical systems and using specialized techniques:

- CAN Bus Systems: Understanding and diagnosing CAN (Controller Area Network) bus systems, which are used to communicate between various electronic control units (ECUs) in the vehicle.

- Fiber Optic Cables: Repairing and splicing fiber optic cables, which are used in some vehicles for audio and data transmission.

- Advanced Diagnostic Tools: Using advanced scan tools and diagnostic software to troubleshoot complex electrical problems.

- Module Programming: Programming and reprogramming electronic control modules (ECMs, PCMs, etc.).

- Wiring Harness Repair: Repairing and rebuilding damaged wiring harnesses.

- Custom Wiring: Designing and installing custom wiring systems for aftermarket accessories.

8. Safety Precautions for Auto Wiring Repair

What safety measures should technicians follow during auto wiring repair? Always disconnect the battery, wear safety glasses, and avoid working in wet conditions to minimize risks.

Safety should always be a top priority when performing auto wiring repair:

- Disconnect the Battery: Always disconnect the negative battery cable before working on electrical systems.

- Wear Safety Glasses: Protect your eyes from sparks, debris, and chemicals.

- Use Insulated Tools: Use tools with insulated handles to prevent electrical shock.

- Avoid Working in Wet Conditions: Never work on electrical systems in wet or damp conditions.

- Be Aware of Airbag Systems: Airbag systems can be dangerous if not handled properly. Consult the vehicle’s service manual before working near airbags.

- Use Proper Ventilation: Work in a well-ventilated area when soldering or using chemicals.

- Follow Manufacturer’s Instructions: Always follow the manufacturer’s instructions when using tools and equipment.

9. Choosing the Right Auto Wiring Repair Training Program

How can you select the best auto wiring repair training program? Look for accredited programs with experienced instructors, hands-on training, and industry-recognized certifications.

Choosing the right auto wiring repair training program is essential for building a successful career:

- Accreditation: Look for programs that are accredited by reputable organizations, such as the ASE Education Foundation.

- Curriculum: Review the curriculum to ensure that it covers the topics you need to learn.

- Instructors: Choose a program with experienced and certified instructors.

- Hands-On Training: Look for programs that offer plenty of hands-on training in a real-world shop environment.

- Industry-Recognized Certifications: Check if the program offers industry-recognized certifications, such as ASE certifications.

- Job Placement Assistance: Ask about job placement assistance to help you find a job after graduation.

10. Career Opportunities in Auto Wiring Repair

What career paths are available for skilled auto wiring technicians? Opportunities range from automotive technician to electrical specialist and shop foreman, offering diverse growth potential.

A solid foundation in auto wiring repair can lead to a variety of rewarding career opportunities:

- Automotive Technician: Diagnose and repair electrical and mechanical problems on vehicles. According to the U.S. Bureau of Labor Statistics, the median annual wage for automotive service technicians and mechanics was $46,830 in May 2022.

- Electrical Specialist: Specialize in diagnosing and repairing complex electrical systems.

- Diagnostic Technician: Focus on using diagnostic tools and techniques to identify vehicle problems.

- Shop Foreman: Supervise and coordinate the work of other technicians in an auto repair shop.

- Service Manager: Manage the service department of an auto dealership or repair shop.

- Mobile Mechanic: Provide on-site repair services to customers at their homes or workplaces.

- Auto Electrician: Focusing specifically on the electrical systems of vehicles.

- Specialized Automotive Technician: Focusing on electrical components of certain vehicle types such as hybrids or electric vehicles.

11. Starting Your Own Auto Repair Shop: A Comprehensive Guide

What steps are involved in opening your own auto repair shop? Developing a business plan, securing funding, finding a location, and obtaining necessary licenses are crucial first steps.

Starting your own auto repair shop can be a challenging but rewarding venture. Here’s a comprehensive guide to help you get started:

- Develop a Business Plan: Create a detailed business plan that outlines your goals, strategies, and financial projections.

- Secure Funding: Determine how much funding you will need to start your business and explore your financing options. The U.S. Small Business Administration (SBA) offers resources and programs to help small businesses get funding.

- Find a Location: Choose a location that is accessible to customers and has enough space for your shop.

- Obtain Licenses and Permits: Obtain all the necessary licenses and permits to operate your business legally.

- Purchase Equipment: Purchase the equipment you will need to perform auto repairs, such as lifts, diagnostic tools, and hand tools.

- Hire Qualified Technicians: Hire skilled and experienced technicians to provide quality repair services.

- Market Your Business: Promote your business through advertising, social media, and word-of-mouth.

- Provide Excellent Customer Service: Provide excellent customer service to build a loyal customer base.

12. The Business Side of Auto Repair: Essential Tips for Success

What are the keys to running a successful auto repair business? Focus on customer service, manage finances wisely, and stay updated with industry trends to ensure long-term viability.

To thrive in the auto repair industry, consider these business tips:

- Customer Service: Focus on providing excellent customer service to build a loyal customer base.

- Financial Management: Manage your finances wisely to ensure profitability and sustainability.

- Marketing and Advertising: Invest in marketing and advertising to attract new customers.

- Employee Management: Hire and retain skilled technicians and provide them with ongoing training.

- Inventory Management: Manage your inventory effectively to minimize costs and ensure that you have the parts you need.

- Technology: Embrace technology to improve efficiency and customer service.

- Stay Up-to-Date: Stay up-to-date with the latest automotive technology and repair techniques.

13. Staying Up-to-Date with Auto Wiring Technology

How can technicians keep their auto wiring skills current? Participate in ongoing training, attend industry conferences, and read trade publications to stay informed.

The automotive industry is constantly evolving, so it’s essential to stay up-to-date with the latest technology and repair techniques:

- Ongoing Training: Attend training courses and workshops to learn about new technologies and repair methods.

- Industry Conferences: Attend industry conferences and trade shows to network with other professionals and learn about the latest trends.

- Trade Publications: Read trade publications and online resources to stay informed about new products and technologies.

- Online Forums and Communities: Participate in online forums and communities to share knowledge and learn from others.

- Certification Programs: Pursue advanced certifications, such as ASE certifications, to demonstrate your expertise.

14. Frequently Asked Questions (FAQs) About Auto Wiring Repair

What are some common questions about auto wiring repair and training? These include program costs, salary expectations, and the skills needed to succeed in the field.

Here are some frequently asked questions about auto wiring repair and training:

Q1: How much does auto wiring repair training cost?

The cost of auto wiring repair training can vary depending on the length and type of program. Certificate programs may cost a few thousand dollars, while associate’s degree programs can cost significantly more.

Q2: What is the average salary for an auto wiring technician?

According to the U.S. Bureau of Labor Statistics, the median annual wage for automotive service technicians and mechanics was $46,830 in May 2022. However, salaries can vary depending on experience, location, and certifications.

Q3: What skills are needed to become a successful auto wiring technician?

Key skills include diagnostic abilities, electrical knowledge, soldering, crimping, and the ability to read wiring diagrams.

Q4: What are the common challenges in auto wiring repair?

Common challenges include diagnosing intermittent problems, working with complex wiring systems, and keeping up with new technologies.

Q5: What are the benefits of ASE certification?

ASE certification demonstrates your knowledge and skills to employers and customers, and can lead to higher earning potential.

Q6: How long does it take to complete an auto wiring repair training program?

Training programs can range from a few weeks to two years, depending on the level of training and the type of program.

Q7: What is the job outlook for auto wiring technicians?

The job outlook for automotive service technicians and mechanics is projected to grow 5 percent from 2022 to 2032, about average for all occupations, according to the U.S. Bureau of Labor Statistics.

Q8: Can I learn auto wiring repair online?

Yes, there are many online resources and courses available, but hands-on training is essential for developing practical skills.

Q9: What are some essential tools for auto wiring repair?

Essential tools include a multimeter, wire strippers, crimpers, a soldering iron, and wiring diagrams.

Q10: How can I start my own auto repair shop?

Starting your own auto repair shop requires a business plan, funding, a location, licenses, and qualified technicians.

15. AUTO-REPAIR-TRAINING.EDU.VN: Your Partner in Automotive Success

Looking for comprehensive auto wiring repair training and guidance on starting your own auto repair shop? AUTO-REPAIR-TRAINING.EDU.VN offers expert resources to help you succeed.

At AUTO-REPAIR-TRAINING.EDU.VN, we are dedicated to providing you with the knowledge, skills, and resources you need to succeed in the automotive industry. Whether you’re looking to learn auto wiring repair, advance your career, or start your own business, we have the tools and expertise to help you achieve your goals.

Our Services Include:

- Comprehensive Training Programs: We offer a range of training programs designed to equip you with the skills you need to excel in auto wiring repair and other automotive specialties.

- Expert Guidance: Our experienced instructors and mentors provide personalized guidance and support to help you navigate your career path.

- Business Resources: We offer resources and tools to help you start and manage your own auto repair shop, including business plan templates, financial planning tools, and marketing strategies.

- Industry Insights: Stay up-to-date with the latest industry trends and technologies through our informative articles, blog posts, and webinars.

Ready to take the next step in your automotive career?

Contact us today to learn more about our training programs and business resources.

AUTO-REPAIR-TRAINING.EDU.VN

Address: 200 N Michigan Ave, Suite 1500, Chicago, IL 60601, United States

WhatsApp: +1 (641) 206-8880

Website: AUTO-REPAIR-TRAINING.EDU.VN

Don’t wait any longer to pursue your dreams in the automotive industry. Let AUTO-REPAIR-TRAINING.EDU.VN be your partner in success. Contact us today and let’s build your future together!